0102030405

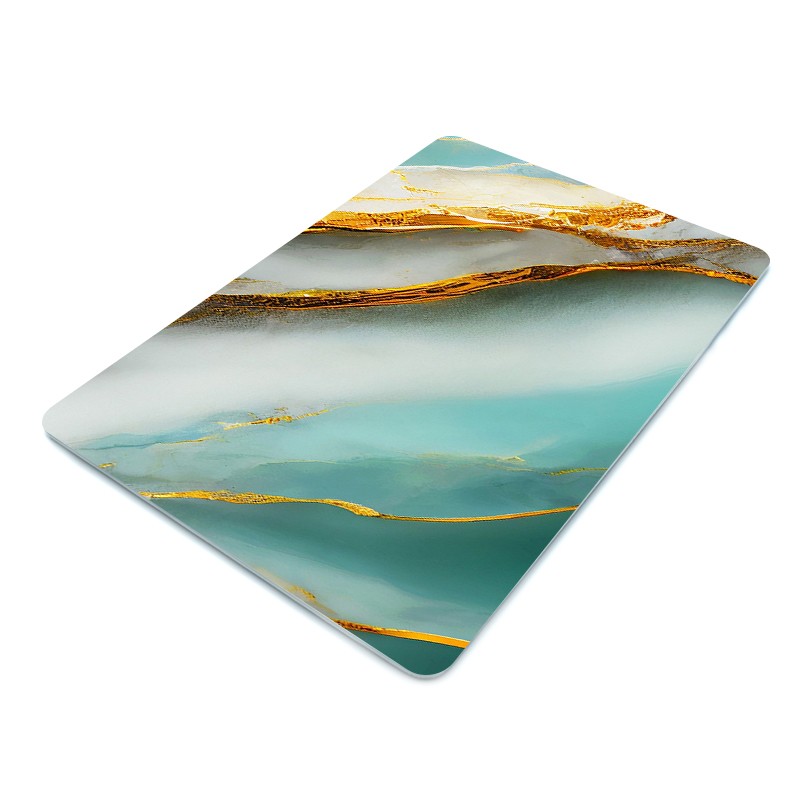

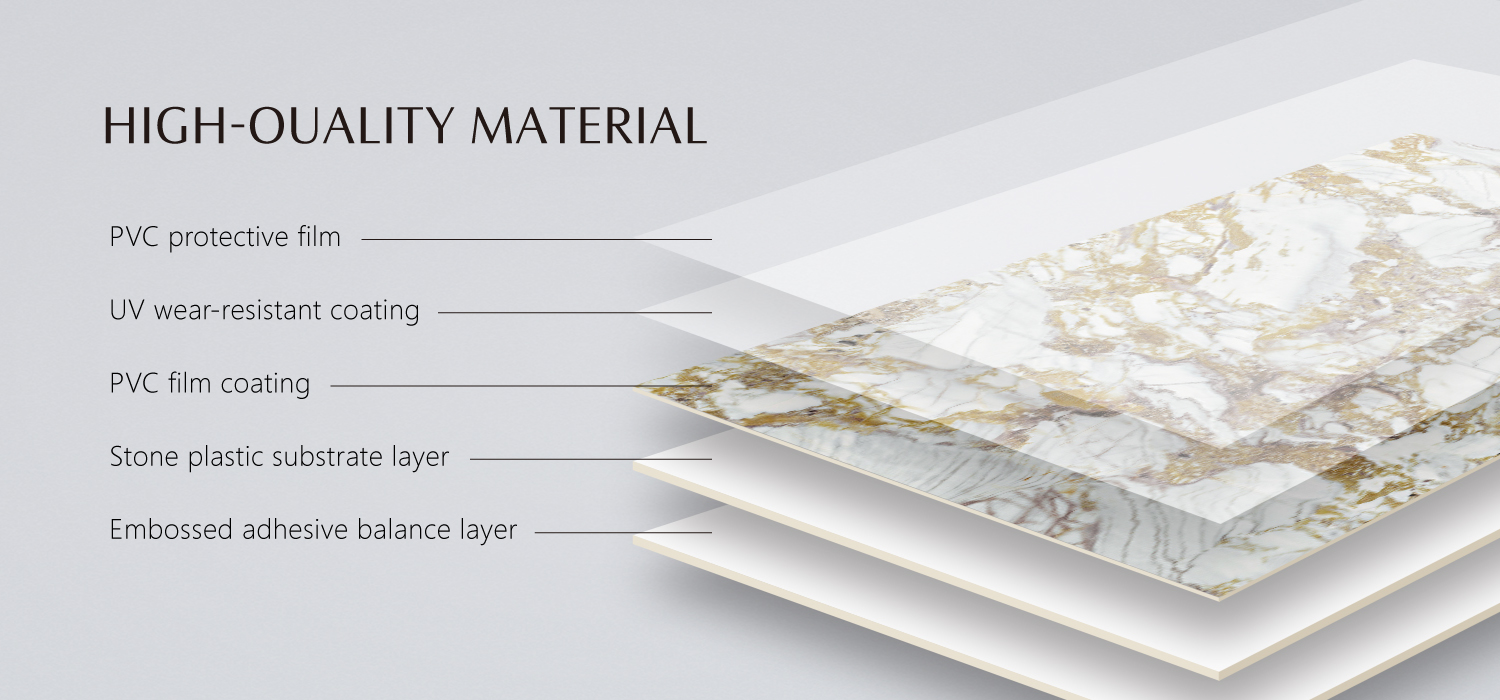

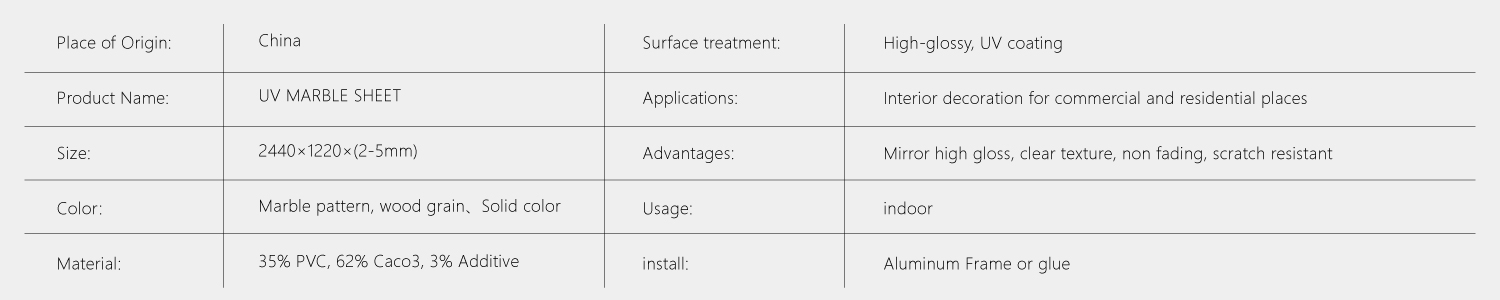

A UV marble innovative wall decoration material that combines 3D printing technology and UV curing technology, which is waterproof, moisture-proof, anti slip, fireproof, and wear-resistant

Products Video

Description

advantage

Environmental friendliness: 3D printed UV marble wall panels use environmentally friendly UV ink, reducing the impact on the environment while adhering to the concept of green printing.

Lightweight and wear-resistant: Compared with natural marble, 3D printed UV marble wall panels are lighter, reducing the load-bearing pressure on the wall, and have characteristics such as waterproof, moisture-proof, anti-skid, fireproof, sound-absorbing, and wear-resistant.

Highly customized: Through 3D printing technology, users can adjust patterns, textures, and even colors according to their preferences, achieving highly personalized customization.

Easy installation: The weight of the wall panel is relatively light, making transportation and installation very convenient. It can be pasted with cement mortar or environmentally friendly adhesive, and the curing time is short, saving construction period.

Application scenarios

3D printed UV marble wall panels are suitable for various scenarios, including:

Family living room and bedroom: adding beauty and personalized design to the home space.

Commercial spaces, such as hotel lobbies and offices, can enhance the overall aesthetics and grade.

Public places: Due to their environmental friendliness and durability, they are also suitable for public places such as schools and hospitals that require high durability and aesthetics.

Production process and design process

Design phase: The designer creates a 3D model on the computer and simulates the actual effect through software to ensure the accuracy and personalized requirements of the pattern.

3D printing: Using specialized 3D printing equipment and UV cured materials for printing, ensuring the accuracy and three-dimensional sense of patterns.

Installation and maintenance: The wall panel is easy to install, uses environmentally friendly adhesive or cement mortar for bonding, and has a short curing time, making it easy to maintain and clean.

Application

Hot Selling

Hot Selling