Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

In recent years, the demand for advanced materials in various industries has surged, leading to the exploration of innovative solutions like the Carbon Crystal Plate. Reports from market research firms indicate that the global advanced materials market is projected to reach over $100 billion by 2025, driven by the need for enhanced performance and sustainability. Carbon Crystal Plates, with their exceptional thermal conductivity and lightweight properties, have emerged as a frontrunner in this sector, offering numerous advantages in applications ranging from electronics to aerospace.

One of the key benefits of Carbon Crystal Plates is their ability to operate efficiently under extreme conditions. According to the Journal of Materials Science, these plates can withstand temperatures exceeding 3000 degrees Celsius, making them ideal for high-temperature applications where traditional materials fail. Additionally, with the increasing emphasis on reducing carbon footprints, the integration of Carbon Crystal Plates aligns with the sustainability goals of many industries, as they can significantly reduce energy consumption in manufacturing processes.

As companies continue to seek cutting-edge solutions to enhance product performance and sustainability, Carbon Crystal Plates represent a valuable investment. Their unique properties not only promise improved efficiency but also contribute to the growing trend of eco-friendly materials. Considering the evolving landscape, now is the opportune time to explore the benefits of incorporating Carbon Crystal Plates into your projects.

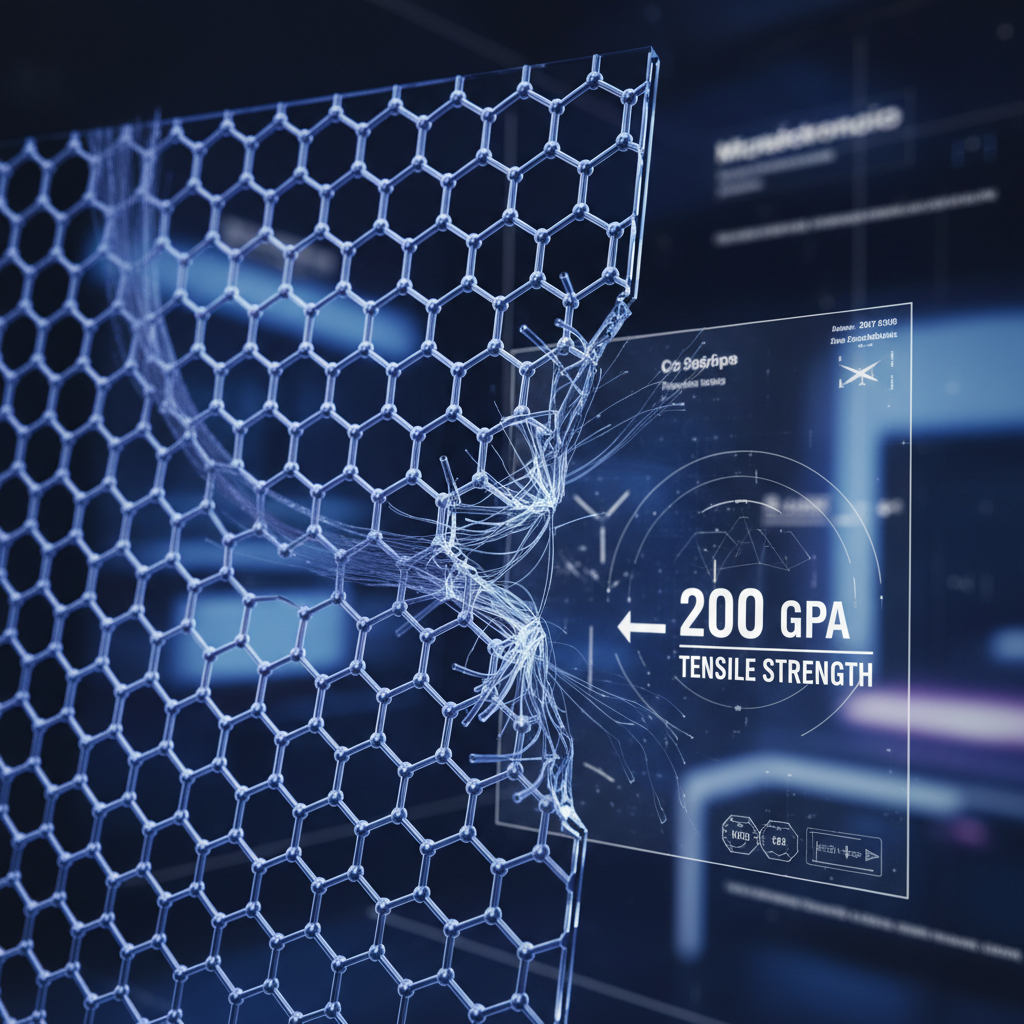

Carbon crystal plates are a revolutionary advancement in material science, composed primarily of carbon atoms arranged in a unique crystalline structure that provides exceptional strength and resilience. According to a report by the International Journal of Materials Science, materials engineered with carbon crystals can exhibit over 200 GPa in tensile strength, significantly outperforming traditional materials such as steel. This remarkable property makes carbon crystal plates an attractive choice for a variety of applications, from aerospace to electronics.

In addition to their impressive strength, carbon crystal plates offer superior thermal conductivity. The Advanced Materials Research journal highlights that these plates can effectively dissipate heat, making them ideal for high-performance applications where temperature regulation is critical. Their lightweight nature, combined with the ability to withstand high temperatures, contributes to energy efficiency in various sectors. As industries increasingly prioritize sustainability and performance, carbon crystal plates emerge as a compelling solution, offering both robustness and environmental benefits.

Carbon crystal plates are revolutionizing various industries with their unique properties and myriad advantages. These plates are known for their exceptional strength, lightweight nature, and remarkable thermal conductivity. In industries ranging from aerospace to electronics, carbon crystal plates help enhance efficiency and durability, making them an excellent choice for high-performance applications. Their ability to withstand extreme temperatures and pressures further solidifies their role in sectors where reliability is crucial.

When considering the transition to carbon crystal plates, it's essential to evaluate your specific needs. **Tip:** Conduct a thorough assessment of your application to determine how these plates can provide improvements in performance and efficiency. Collaborating with industry experts can also offer insights into the most effective uses of carbon crystal technology in your field.

Another advantage of carbon crystal plates is their eco-friendliness, as they can potentially reduce energy consumption and waste in manufacturing processes. **Tip:** Investigate recycling options for carbon materials in your operations to maximize sustainability efforts. With increasing awareness of environmental impact, adopting these plates can not only boost performance but also align your business with eco-conscious practices.

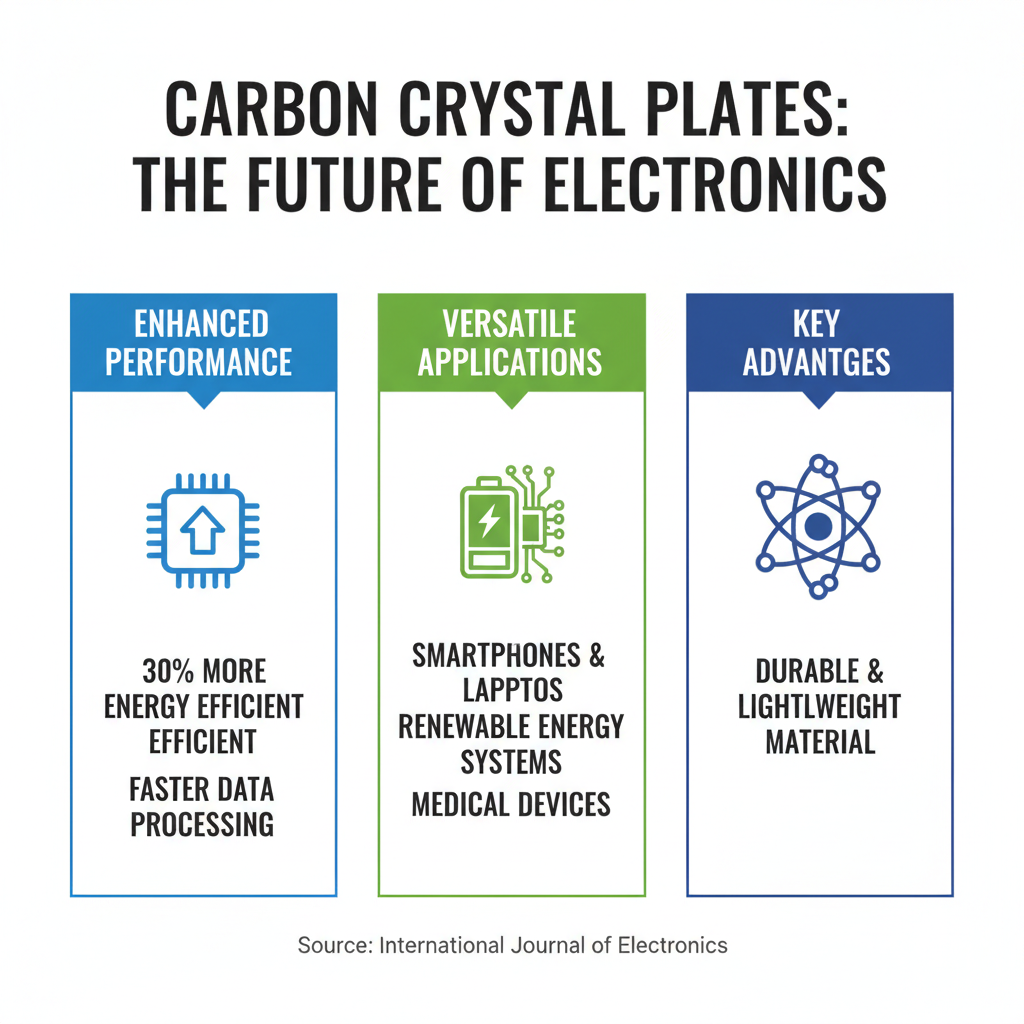

This chart illustrates the key advantages of using carbon crystal plates across various industries. The data highlights the performance improvements, cost-efficiency, and sustainability benefits reported by organizations leveraging these innovative materials.

When comparing carbon crystal plates to traditional materials, the advantages become strikingly evident. Carbon crystal plates, known for their exceptional strength-to-weight ratio, boast a tensile strength that can reach up to 600 MPa, significantly surpassing that of aluminum (approximately 310 MPa) and even steel (around 400 MPa). This makes them particularly valuable in industries where reducing weight without compromising strength is critical, such as aerospace and automotive sectors.

Moreover, the thermal conductivity of carbon crystal plates, calculated at 150 W/mK, offers superior performance over traditional materials like glass and plastic, which often average around 1-5 W/mK. This property promotes better heat dissipation, making carbon crystal plates an ideal choice for electronic applications, especially in high-performance computing environments. As manufacturers increasingly seek materials that enhance energy efficiency and thermal management, the adoption of carbon crystal technology may become a pivotal trend in material science, as evidenced by a recent market report predicting a 15% growth rate in the carbon materials sector over the next five years.

Carbon crystal plates are revolutionizing various fields within technology and science, offering exceptional properties that cater to modern needs. One significant application is in electronics, where carbon crystal plates are utilized to enhance electronic devices' performance. According to a recent report by the International Journal of Electronics, devices using carbon-based materials can achieve a 30% increase in energy efficiency compared to traditional silicon-based options. This property is vital as the demand for energy-efficient solutions grows in our increasingly digital world.

In addition to electronics, carbon crystal plates are gaining traction in the biomedical field. Their biocompatibility and exceptional strength make them ideal for developing medical implants and prosthetics. A study from the Journal of Biomaterials Research showed that carbon-based materials, including carbon crystal plates, can reduce rejection rates in implants by up to 50%. This advancement is crucial for improving patient outcomes and speeding up recovery times.

Tip: When assessing the suitability of carbon crystal plates for your project, consider their thermal management capabilities, which can significantly impact device longevity and performance.

Tip: Stay updated with the latest research and industry reports to make informed decisions, as the field is rapidly evolving with new applications and innovations.

The evolution of carbon crystal plates is poised to revolutionize various industries, driven by ongoing innovations and advancements. Recent reports from the International Data Corporation (IDC) indicate that the global market for advanced carbon materials is projected to reach $12 billion by 2026, with carbon crystal plates playing a significant role. These materials are lauded for their unique properties, including high strength-to-weight ratios and exceptional thermal conductivity, making them ideal for applications ranging from aerospace to electronics.

Future trends highlight a growing focus on enhancing the manufacturing processes for carbon crystal plates. Developments in chemical vapor deposition (CVD) technologies are enabling the production of more uniform and scalable carbon crystal structures. According to a study by the Global Graphene Group, the efficiency of these processes is expected to improve by over 30% in the next five years, resulting in lower costs and increased accessibility for various industries. Furthermore, researchers are exploring the integration of carbon crystal plates in renewable energy applications, particularly in solar cells, which could enhance their efficiency and longevity significantly. As these trends continue to unfold, the adoption of carbon crystal plates could see exponential growth across multiple sectors.