Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

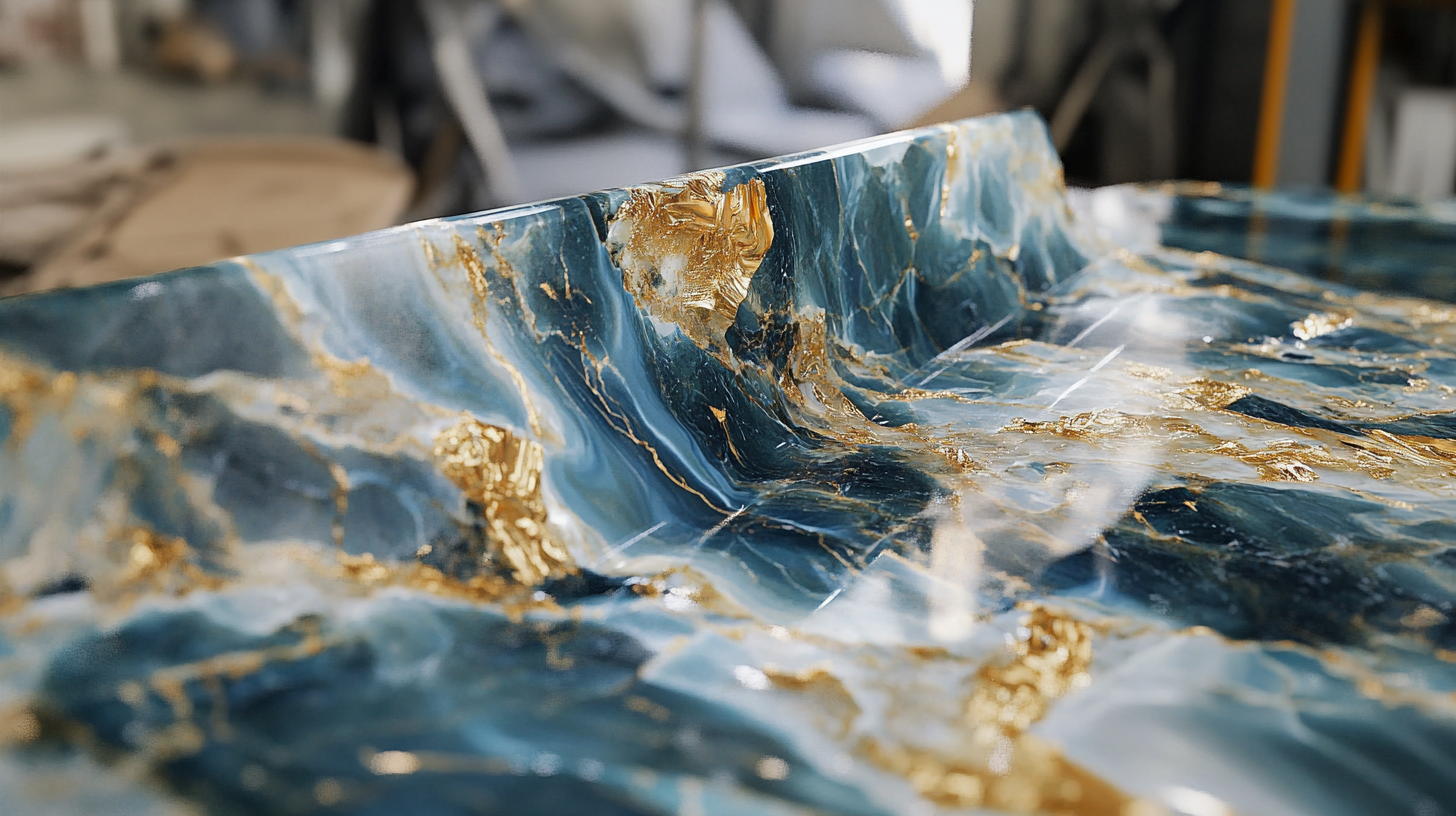

In recent years, China's manufacturing sector has demonstrated remarkable resilience, thriving even amidst the challenges posed by U.S.-China tariffs. According to a report by the International Monetary Fund, China maintained a robust manufacturing growth rate of approximately 8.3% in 2022, effectively countering trade restrictions through innovation and strategic supply chain adjustments. A shining example of this adaptability is the production of 3D UV Marble Sheets, which have gained popularity in both domestic and international markets due to their aesthetic appeal and durability. The global market for decorative surfaces, including advanced materials like 3D UV Marble Sheets, is projected to reach $325 billion by 2026, reflecting the increasing demand for quality and design in construction and interior design. As Chinese manufacturers continue to leverage their strengths in technology and production capabilities, they not only defy the odds but also enhance their competitive position in the global marketplace.

China's manufacturing sector demonstrates remarkable resilience in the face of ongoing tariff challenges, particularly from the United States. Despite high tariffs, data indicates a steady growth in China's foreign trade, with a 2.4% increase in total goods imports and exports in the first four months of this year. Exports alone witnessed a robust growth of 7.5%, signifying China's strong international competitiveness. In response to these economic pressures, companies are innovating and adapting their strategies.

**Tip:** To enhance your business adaptability, consider diversifying your supply chains and exploring new markets to mitigate risks associated with tariff fluctuations.

Furthermore, events like the recent Canton Fair highlight the unwavering vitality of China's foreign trade environment. The fair attracted global buyers, reaffirming confidence in Chinese products despite geopolitical tensions.

**Tip:** Engage with emerging markets and digital platforms to capture new opportunities. Utilizing technology in international trade can provide valuable insights and open doors to a wider audience.

China's commitment to expanding its open market policies further underlines its ability to navigate through uncertainties and maintain economic momentum.

The recent advancements in 3D UV marble sheet technology are significantly influencing the manufacturing landscape in China, driving industry growth even amidst ongoing US-China tariff challenges. According to a report by MarketsandMarkets, the global market for 3D printing materials is projected to reach $12.9 billion by 2025, with a notable portion attributed to decorative surfaces like marble sheets. These innovative materials not only provide aesthetic appeal but also offer durability and cost-effectiveness, making them an attractive choice for various applications, from interior design to commercial products.

Furthermore, the integration of advanced digital printing techniques has enhanced the quality and versatility of 3D UV marble sheets. A study from Grand View Research indicates that the decorative surfacing market is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2020 to 2027. This growth can be partially attributed to the increased adoption of UV printing technology, which allows for intricate designs and vibrant colors to be applied to various substrates. As manufacturers in China continue to innovate and adapt to market demands, the utilization of 3D UV marble sheets presents a promising avenue for sustained growth and competitive advantage in the global market.

Chinese manufacturers are navigating the complexities of the tariff landscape imposed by the United States with innovative strategies, ensuring that production continues to thrive, particularly in specialized sectors like 3D UV marble sheet manufacturing. According to a report from the China National Textile and Apparel Council, despite tariffs peaking at 25% for many goods, Chinese exports in certain high-value industries, including advanced materials, have seen a growth of approximately 9% year-over-year. This resilience underscores the adaptability of Chinese manufacturers in leveraging local resources, optimizing supply chains, and focusing on high-quality outputs.

To combat the impact of tariffs, many Chinese manufacturers are also investing in technology and automation. A study by the Ministry of Industry and Information Technology showed that over 50% of manufacturers have integrated smart manufacturing practices, which not only enhance production efficiency but also reduce costs in the long run. Additionally, companies are increasingly turning to export markets beyond the US, with Southeast Asian nations witnessing a 15% increase in imported goods from China, highlighting a strategic redirection that mitigates the direct fallout from US tariffs. By employing these proactive measures, Chinese manufacturers are not just surviving but thriving in an ever-challenging global trade environment.

This chart illustrates the growth of China's manufacturing output over the past five years, despite the introduction of US tariffs. It highlights the resilience of Chinese manufacturers and their strategies to maintain production levels.

The ongoing US-China tariff war has undeniably impacted global supply chains, yet China's manufacturing sector continues to demonstrate resilience and adaptability. According to a report by the World Trade Organization, Chinese exports in 2022 reached approximately $3.59 trillion, showcasing a remarkable capacity to navigate through trade tensions. Despite the tariffs, Chinese manufacturers have embraced technological advancements and optimized production processes, with sectors like 3D UV marble sheets thriving. This segment alone reports a substantial annual growth rate of 8%, driven by increasing demand for innovative decor solutions.

**Tips for Businesses:**

1. Diversify your supplier base to mitigate risks associated with trade restrictions. Forming partnerships with manufacturers in other countries can help maintain a steady supply chain.

2. Invest in technology to enhance production efficiency. Automation and smart manufacturing can not only reduce costs but also improve product quality, making your business more competitive despite tariff pressures.

Furthermore, as international consumers seek alternatives to products affected by tariffs, Chinese manufacturers are exploring new markets in Southeast Asia and Africa. Data indicates that exports to these regions have surged by over 20%, proving that adaptability and market exploration can offset the challenges posed by tariffs. The continued evolution of the Chinese manufacturing landscape signals optimism in the face of adversity.

| Sector | 2019 Exports (Billion USD) | 2020 Exports (Billion USD) | 2021 Exports (Billion USD) | Impact of Tariffs |

|---|---|---|---|---|

| Textiles | 36.2 | 33.4 | 40.1 | Moderate |

| Electronics | 58.6 | 52.8 | 60.2 | High |

| Machinery | 48.1 | 45.3 | 50.5 | Moderate |

| Automobiles | 11.7 | 9.1 | 15.2 | Low |

| Furniture | 25.5 | 22.3 | 27.8 | Low |

Despite the challenges presented by US tariffs, the future of Chinese manufacturing appears promising, driven by the need for a robust domestic demand framework. As highlighted by Zhang Jun, the key to overcoming the development constraints in the manufacturing sector lies in establishing a strong internal cycle of demand. This strategic shift is crucial, especially in an era marked by fluctuating global economic conditions and restructuring international order.

While tariffs disrupt the international expansion of Chinese enterprises, they also present unique opportunities for growth and innovation within the country. Manufacturers are increasingly leaning toward technology-rich solutions, such as advanced materials like the 3D UV marble sheet, which not only enhance product offerings but also cater to an evolving market. As Chinese firms adapt to the changing landscape, they can leverage local demands to foster resilience, further solidifying their position in the global market. This adaptability will not only sustain their operations but will also potentially lead to a redefined global manufacturing paradigm.