Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

The rise in demand for sustainable building materials has led to WPC panels being a rather trendy alternative among global buyers seeking to add an aesthetic and functional flavor to their projects. Shandong Xiangying New Materials Technology Co., Ltd. is leading this trend through the supply of high-quality WPC panels that showcase the best of both worlds: wood and plastic. In the present blog, we will focus on the important technical specification of WPC panels that every global buyer should keep in mind while selecting materials for construction, landscaping, or interior design.

Understanding these technical specifications is critical to ensuring that WPC panels do not only meet standards for durability and performance but also fulfill the requirements of various applications.

From moisture resistance to UV protection, the very characteristics of WPC panels can either prolong or erode their serviceability. Shandong Xiangying New Materials Technology Co., Ltd. prides itself on providing expert opinions and trustworthy products to help buyers make the right decision. Come along as we assess the fundamental ingredients of WPC panels that will motivate your projects for a sustainable tomorrow!

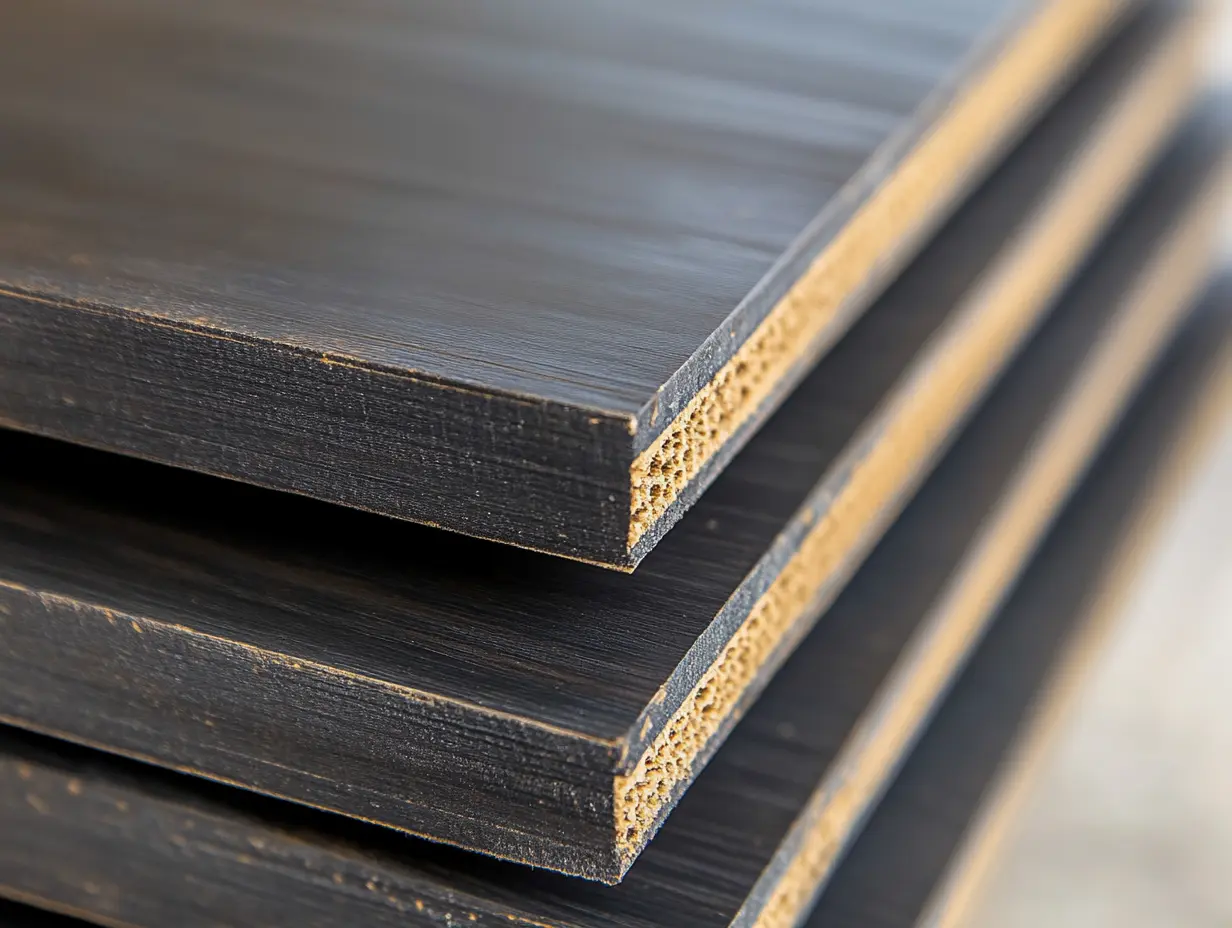

When analyzing technical specifications for wood plastic composite WPC panels, several major factors must be weighed by global buyers in order to ascertain educated purchasing principles. One such factor is the material composition: broadly speaking, WPC panels are composed of wood particles mixed with thermoplastic material. Such a combination greatly affects panel durability and strength; however, these variables also play a role in their aesthetic appeal and environmental impact. Panel dimensional stability and moisture resistance are key specifications as well. WPC panels are treaded not to buckle under different weather conditions, so they find utility in indoor as well as outdoor applications. Also, in considering the appointment, buyers need to look at the manufacturing process since new technology can potentially enhance the WPC product performance in terms of longevity and overall minimization of maintenance. Specification-wise, this gives buyers the ability to judge the quality and fit for purpose concerning their WPC.

It is very important that international buyers learn about the essential material components when delving into the manufacture of wood plastics composite (WPC) panels. Much of a WPC panel involves a thermoplastic or thermoplastics that has been mixed with wood fibers or flour, often incorporating some recycled material. These blends improve the mechanical properties of the panels and therefore constitute a sustainable alternative to the creation of landfill waste.

Other Additives Necessary for wood and plastic Components are UV Stabilizers, Colorants, and Fungicides. Such materials increase the durability of the WPCs to make them weatherproof, decay proof, and finish in a way to allow use of various architectural styles. Knowledge about those materials will help the buyer understand their purchase of WPC panels in his or her project.

Global buyers who care for quality and longevity in building material must understand the actual manufacture of WPC (Wood Plastic Composite) panels. The manufacturing process starts with proper preparation of raw materials, which consists of mixing wood fibers with thermoplastics. The mixture is then subjected to heat and pressure and extruded into different shapes and sizes for various applications.

Ensuring quality control is another vital part of the process. Manufacturers carry out rigorous tests to ensure the strength and durability moisture performance of the panels. Environmental responsibilities are prevalent in such manufacture processes where the use of recycled materials is undertaken. This reduces high trash for disposal and satisfies the conscience of some customers. Learning the fore-standing specifications will help in making an informed choice whereby buyers will be able to choose products suitable for their projects.

Assessing the strength and durability ratings of WPC panels should relate with an understanding by global buyers that these materials perform sustainably. WPC panels, which are resistant to moisture and decay, then receive high durability ratings, fit to be applied for several applications from decking to wall cladding. Such resistance to harsh environmental conditions thus renders WPC panels a favorable alternative to traditional wood products.

The global emphasis on eco-friendliness has made it even more urgent to talk about sustainable materials. Rising global temperatures and climate-related discussions make the case for incorporating durable WPC panels, which will reduce the reliance on not-so-sustainable building materials. Making these efforts complement the growing demand worldwide for greener alternatives, especially solar energy, evidenced by rising solar panel installations and exports in places like India.

WPC panels, also known as Wood Plastic Composite panels, are increasingly being recognized for many applications across a multitude of industries. The properties conferred by both wood and plastic are present in these panels, making the material light yet durable, thus enabling its applications for construction, furnishing, and decoration. Buyers should give heed to technical specifications, such as density, moisture resistance, and thermal stability, which play an incredibly significant role in the performance and longevity of WPC products.

In the global market, the WPC panels have found quite a bit of demand in outdoor applications, such as decking and fencing, due to their weather resistance and low maintenance requirements. With international trade events connecting buyers and sellers all over the world, knowledge of the applications and specifications of WPC panels will facilitate informed decisions among global buyers to take maximum advantage of this advanced material.

On the technical side of WPC panel specifications, the buyer must be aware of global technical norms. Certifying against global standards ensures that the panels conform to sustainable and performance criteria. Certification must be sought for the actual materials and manufacturing process from an environmental and durability perspective.

Just as other industries from textile to smart and sustainable solutions are undergoing change, the WPC field is seeing change. Demand for eco-friendly materials concert e with the global technical textile, forecasted to grow at more than USD 241.5 billion by 2035. Buyers should keep abreast of these developments to assess how recent innovations and certifications related to WPC panels can reinforce their product line and meet consumer expectations.

WPC panels market has seen a lot of exciting trends, the most interesting of which, perhaps, are innovations that have totally transformed the world in which they are viewed. For example, expansion into new territories by companies, such as the North American market, has turned the tables on them. Such activity is even more critical for businesses seeking to increase their global footprints and access new opportunity spaces. It is driven by growth ambitions, targeted towards significant growth, indicative of the increased demand for sustainable building materials like WPC panels.

Besides territorial expansion and technological changes in the production of WPC panels, innovations are changing. Panel durability and appearance are getting important to manufacturers regarding end-users' perception of greener and greener construction solutions. As market dynamics change, these trends and the resulting changes in the buyer market will be of importance for global buyers making their choices in this changing face of WPC panels.

This text reads:

Compare and investigate some of the important technical specifications pertaining to the WPC panel as compared to traditional materials, which highlight the advantages. WPC panels provide a composite of wood and plastic material that has better resistance to weatherrelated problems as compared to decay and attack by pests than wood materials. This quality gives extreme external performances in applications besides locations with higher moisture.

WPC panels also provide flexibility and easier installation when compared to other materials. They are lightweight, making transportation economical-preferred materials for installation since they eliminate extensive labor-related installation procedures. In addition, the finishes on the surface of WPC material can be engineered to look like the natural appearance of wood. Finally, the aforementioned technical benefits combine to provide a plausible reason why so many global buyers are converting to WPC panels as reliable, durable, and sustainable materials in construction and design.

WPC personal and unlike their counterparts with meaningful variation. Apart from these, there are a thousand more benefits that WPC panels are supposed to deliver. Performance-wise, some in-built properties have made these panels perfect for almost all outdoor environments. WPC panels are expected to last longer, as well as withstand all weather conditions, rot, and pest infestation, unlike wood materials. WPC will, therefore, be the most excellent building material for installing things outdoors or in regions vulnerable to moisture.

Now, WPC panels become famous as all other flexible materials and are very easy to install. They are much lighter than other materials, thus has saved transportation cost and labor cost for installation. WPC surface finishes can also be engineered to look like natural wood finishes; thus saves the aesthetics without compromising performance. These combinations of technical merits indicate why more and more buyers worldwide are moving to WPC panels for reliable and sustainable alternatives in construction and design.

Consolidating information relevant to the point and comparing WPC panels to traditional materials enables an even critical look into their property. WPC panels create a composite of wood fibers and plastic, which can be more resistant to weathering, rotting, and different pests compared to the common wooden materials. This advantage ensures that WPC be considered an ideal outdoor and wet application.

WPC panels further are done with enhanced flexibility and easy installation, as compared to most materials. The lighter weight has made the transport economical compared with using other materials, which needs extensive labor-related installation procedure as well. In addition, the finishes on the surface of WPC material can be engineered to look like natural appearance of wood. Finally, all these technical advantages join hands into a very plausible argument as to why so many global buyers are turning towards WPC panels-the material becomes really very much reliable, durable and sustainable for construction and design.

Wood-plastic composite (WPC) products have gained ground in evaluating their effect on the environment and sustainability as they have been increasingly preferred worldwide by potential customers for eco-friendly construction materials. WPC panels, made from recycled plastics and wood fibers, gave lower amounts of carbon footprints than those from other traditional materials, thus making them one of the viable alternatives for green construction applications.

The property of WPC and indeed the major benefit is its endurance as well as moisture resistance, which means that the life cycle gets longer while replacements reduce significantly. This brings about less waste generation as well as resource extraction. Additionally, the processes of WPC production tend to utilize more of post-consumer raw materials. This would go a long way in ensuring that the growing demands of the construction field for greener options are satisfied while equipping buyers with knowledge on what WPC panels entail to make decisions that can impact the environment positively.

The Global customers should consider some of the most important technical specifications when choosing any quality WPC panels, so that the panels also last long and deliver great performance. First of all is the composition of the material. Most high-quality WPC panels really comprise a fairly balanced ratio of wood fibers to polymers, so making it strong and resistant to the weather. You should also keep track of this ratio of wood to plastic, because it's very much linked to the panel's mechanical properties and its lifetime.

Another very important area to look into is the manufacturing system. The newest production processes as, say, co-extrusion, offer an elegant surface as well as higher resistance to scratches and fading. The needful certifications should be taken care of concerning standards in the industry, thus guaranteeing optimal performance under different environmental conditions. Lastly, you may consider the warranty over this product as offered by the manufacturer because such value shows how much he trusts the quality and durability of his product. In this way, the buyers can be well informed regarding these specifications while deciding on the quality of the WPC panel that will furnish their needs.

The affluent buying customers are required to quote importance to the several very essential technical specification to guarantee the quality and durability performance of selected panels in any part of the world. The first one on such considerations should be material composition. Most high-quality WPC panels comprise quite balanced ratios of wood fibers and polymers, thus making them strong and, at the same time, weather resistant. Also, check the ratio of wood to plastic because it is really very much related to the mechanical properties of the panel and its lifetime.

Another important factor for consideration is manufacturing. Advanced production nowadays, such as co-extrusion, not only improves the surfacing but also makes the product more resistant to scratches and fading. Buyers must closely check the certificates of compliance with international standards because they serve as assurance that the panels will perform optimally under the different conditions of the environment. In the final leg, warranty is considered as offered by the manufacturer. That speaks volume about the quality and durability of the product. This is how buyers will objectively have informed decisions when selecting the best quality WPC panels for their needs.

WPC panels typically consist of a combination of wood fibers and thermoplastics, which affects their durability, strength, aesthetic appeal, and environmental impact.

Dimensional stability ensures that the panels can withstand varying weather conditions, making them suitable for both indoor and outdoor applications.

Buyers should look for advanced production techniques, such as co-extrusion, which enhance surface finish and improve resistance to scratches and fading.

The ratio of wood to plastic directly impacts the mechanical properties and longevity of the WPC panels; a balanced blend is crucial for strength and weather resistance.

Certifications that verify compliance with industry standards are important as they ensure that the panels perform well under various environmental conditions.

A warranty reflects the manufacturer’s confidence in the product's quality and durability, giving buyers assurance of their investment.

Moisture resistance is critical for preventing damage and maintaining the integrity of WPC panels when exposed to varying humidity and weather conditions.

Global buyers should prioritize material composition, manufacturing process, and warranties to ensure they select durable and high-performing WPC panels.

Advancements in technology can enhance the performance of WPC products, leading to greater longevity and reduced maintenance costs.

Understanding the technical specifications allows buyers to assess the quality and suitability of WPC panels for their specific needs and applications.