PRODUCT

INTRODUCTION

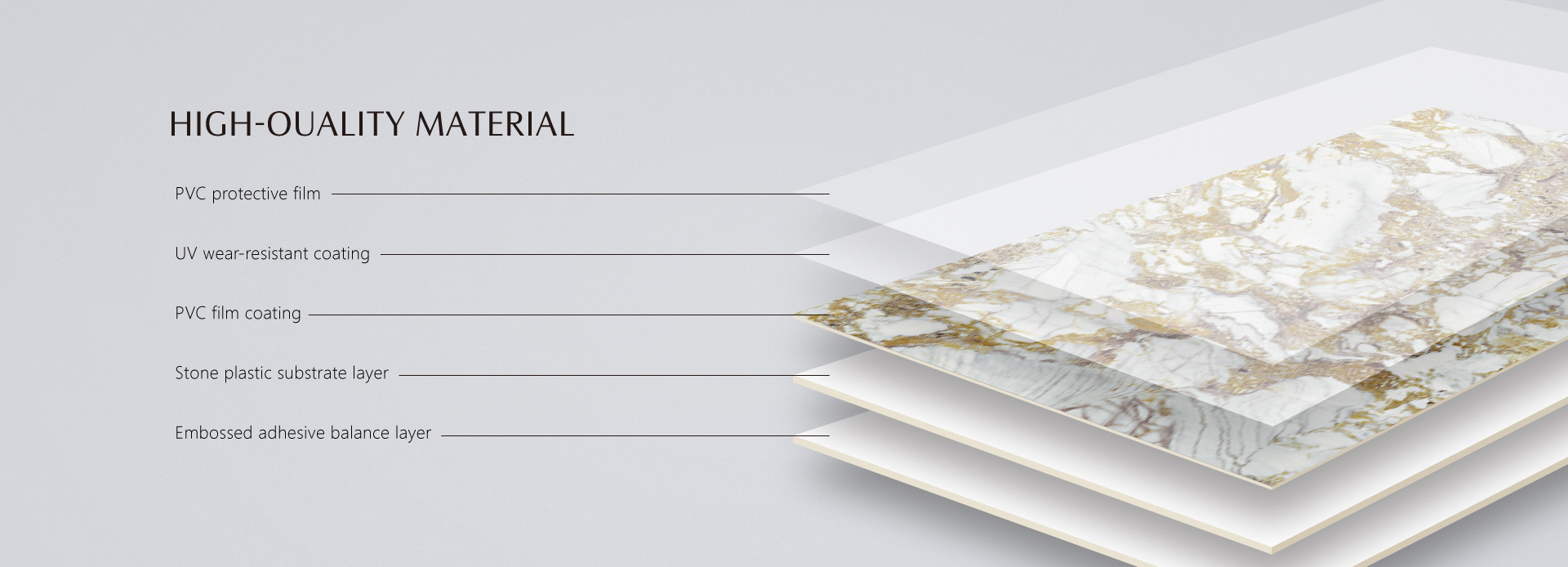

UV marble sheet is made of high-density calcium carbonate powder, PVC, and additives as substrates. The surface of the board is coated and decorated through UV light curing technology, and then dried by a UV light curing machine to form a board with a protective layer.

PRODUCT INTRODUCTION

| Place of Origin: | China | Surface treatment: | High-glossy, UV coating |

| Product Name: | UV MARBLE SHEET | Applications: | Interior decoration for commercial and residential places |

| Size: | 2440×1220×3mm | Advantages: | Mirror high gloss, clear texture, non fading, scratch resistant |

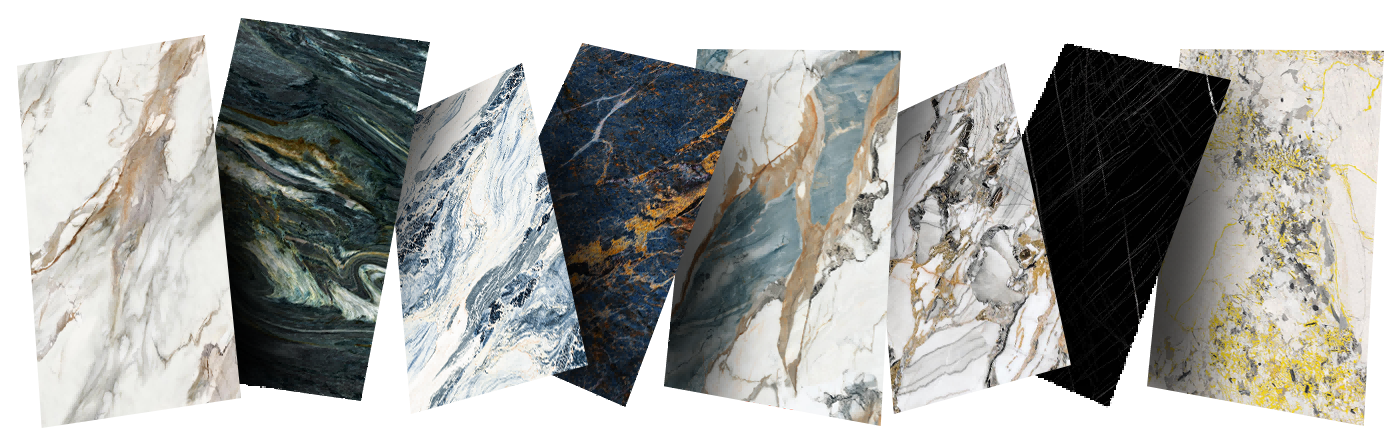

| Color: | Marble pattern, wood grain、Solid color | Usage: | indoor |

| Material: | 35% PVC, 62% Caco3, 3% Additive | install: | Aluminum Frame or glue |

HIGH SURFACE SMOOTHNESS

The mirror highlight effect is obvious

Rich texture, not easy to fade, no color difference

ENVIRONMENT PROTECTION

Does not contain volatile substances such as benzene

UV curing to form a dense cured film

-

Features and Advantages

+ -Wear resistant and acid alkali resistant:

The surface treated with UV has high hardness, is wear-resistant and acid alkali resistant, and is suitable for indoor and outdoor decorative use.

Environmental Protection:

The substrate material itself is environmentally friendly, and the UV treatment technology is non-toxic and harmless, ensuring the health and safety of residents.

Aesthetics:

UV marble sheet can simulate the texture and color of marble, with excellent visual effects, suitable for various decoration styles.

Durable:

After UV treatment, the surface hardness increases, and the wear resistance and scratch resistance are significantly improved, extending the service life.

Easy to maintain:

The surface is smooth and delicate, easy to clean and maintain.

-

Product Catalog

+ - -

Application Scenarios

+ -UV marble sheet are widely used in fields such as building decoration, home decoration, and art production due to their superior performance and beautiful appearance. It has a wide range of applications in areas such as floors, walls, countertops, sculptures, etc. Especially in places that require a quiet environment, such as hospital wards, school libraries, etc., its sound-absorbing effect has been fully utilized.

Hot Selling

Hot Selling