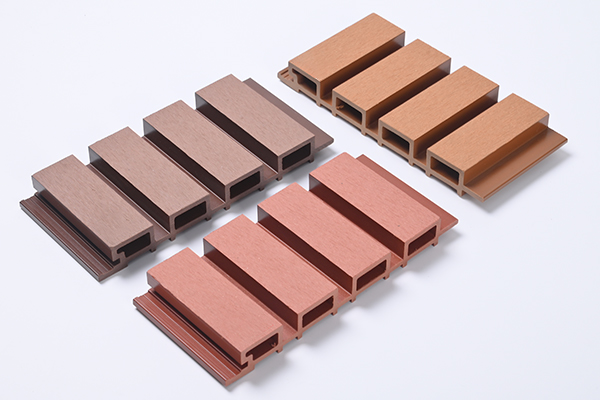

PRODUCT

INTRODUCTION

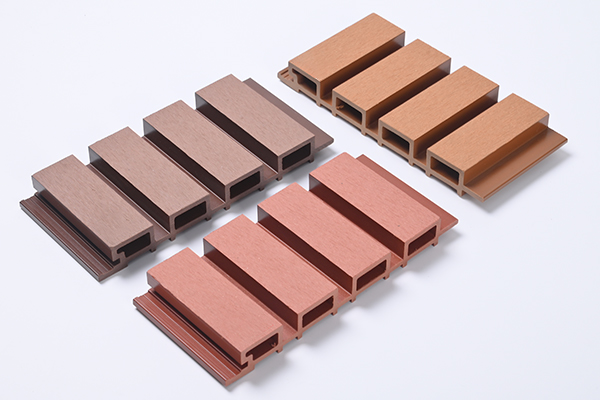

Wood plastic composite wall panels are actually made by using wood as the base material, and then processing it with certain plastic materials and additives. lt needs to be thoroughly stirred, then heated by the mold to form the final panel.

PRODUCT INTRODUCTION

| Place of Origin: | China | Applications: | Building exterior walls, courtyard fences |

| Product Name: | Wood plastic composite wall panel | Advantages: | Environmental protection, weather resistance, fire resistance, waterproofing |

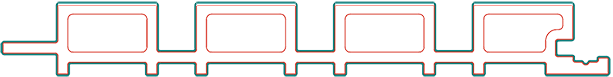

| Model: | XY-219-26 | Usage: | Outdoor |

| Material: | Wood plastic composite material | install: | Fix directly on the support beam with screws |

| Surface treatment: | Wire drawing, embossing | Service life: | Over 25 years |

SELECTED RAW MATERIALS

Natural wood fiber as the main raw material

Application of Polyethylene Filling Modification and Polymer Interface Chemistry

Processing adjuvant

WOOD PLASTIC COMPOSITE

wood powder+Polyethylene+additives

Below EO level standard

Non polluting, pollution-free and recylable

Free of benzene substances

Can be 100% recycled, reused, and reprocessed for use

Good physical and mechanical properties

High load-bearing capacity, not easily deformed, with a service life of over 25 years

Good water resistance, not susceptible to insect infestation or fungal growth

Acid and alkali resistance, corrosion resistance

Low temperature deformation degree: length 0.09%/width 0.15%

Cracking degree:375%

Waterproof (water absorption rate):1.50%

Anti corrosion: up to GB l

-

Features and Advantages

+ -Weather resistance:

WPC outdoor wood plastic wall panels can resist ultraviolet rays, moisture, and corrosion, and adapt to changing climate conditions.

Low maintenance cost:

Not easy to crack and deform, reducing maintenance frequency and cost.

Environmental Protection:

Made from recycled wood fibers and plastics, it contributes to green building and sustainable development.

Easy installation:

Prefabricated panel design saves construction time and costs.

Beautiful and diverse:

Imitate various wood textures to meet personalized aesthetic needs.

Waterproof and moisture-proof:

It can effectively prevent decay and expansion deformation in damp and wet environments.

Insect and termite prevention:

It can effectively prevent insect harassment and extend its service life.

High environmental friendliness:

Recyclable, saving wood usage.

-

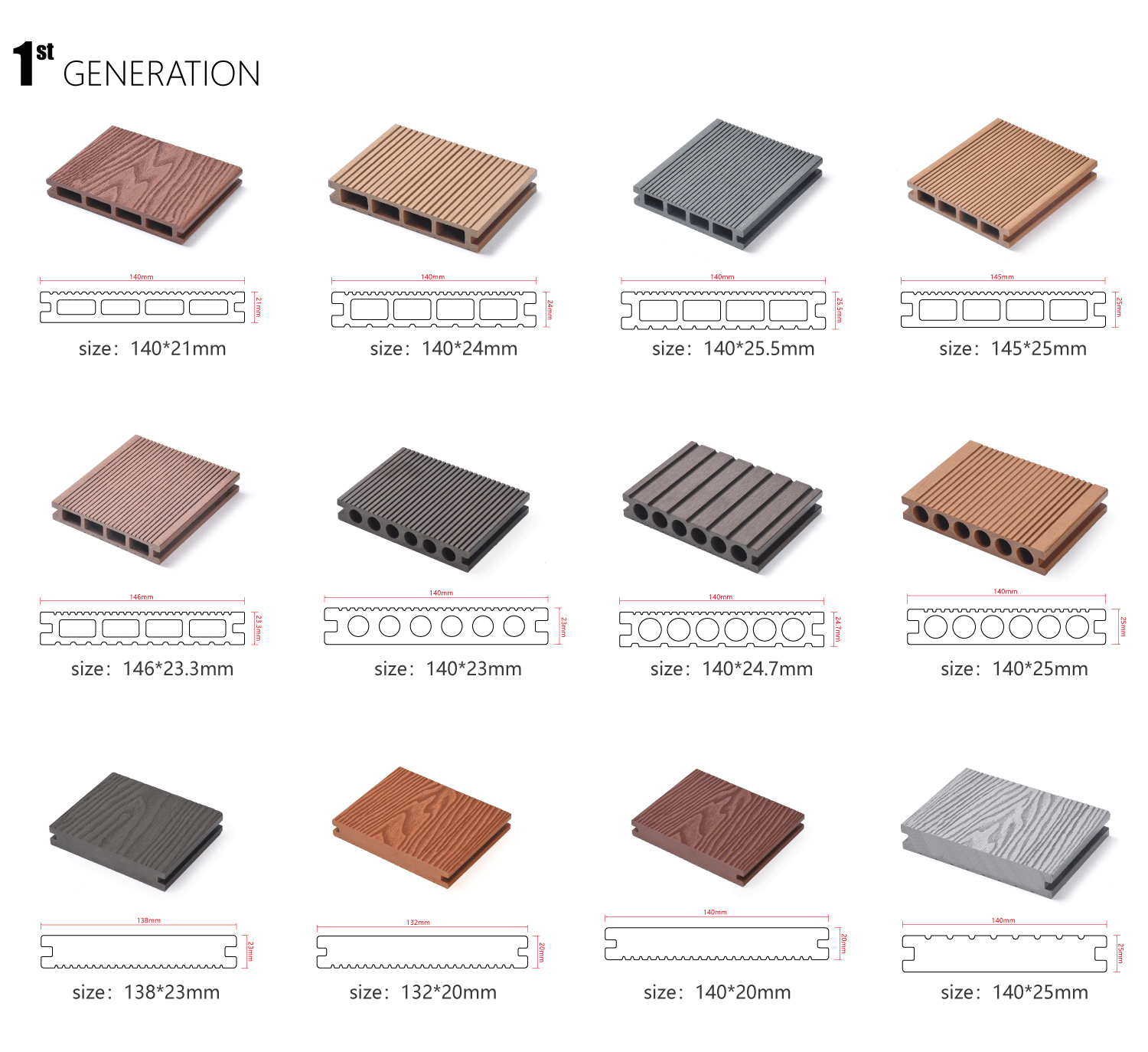

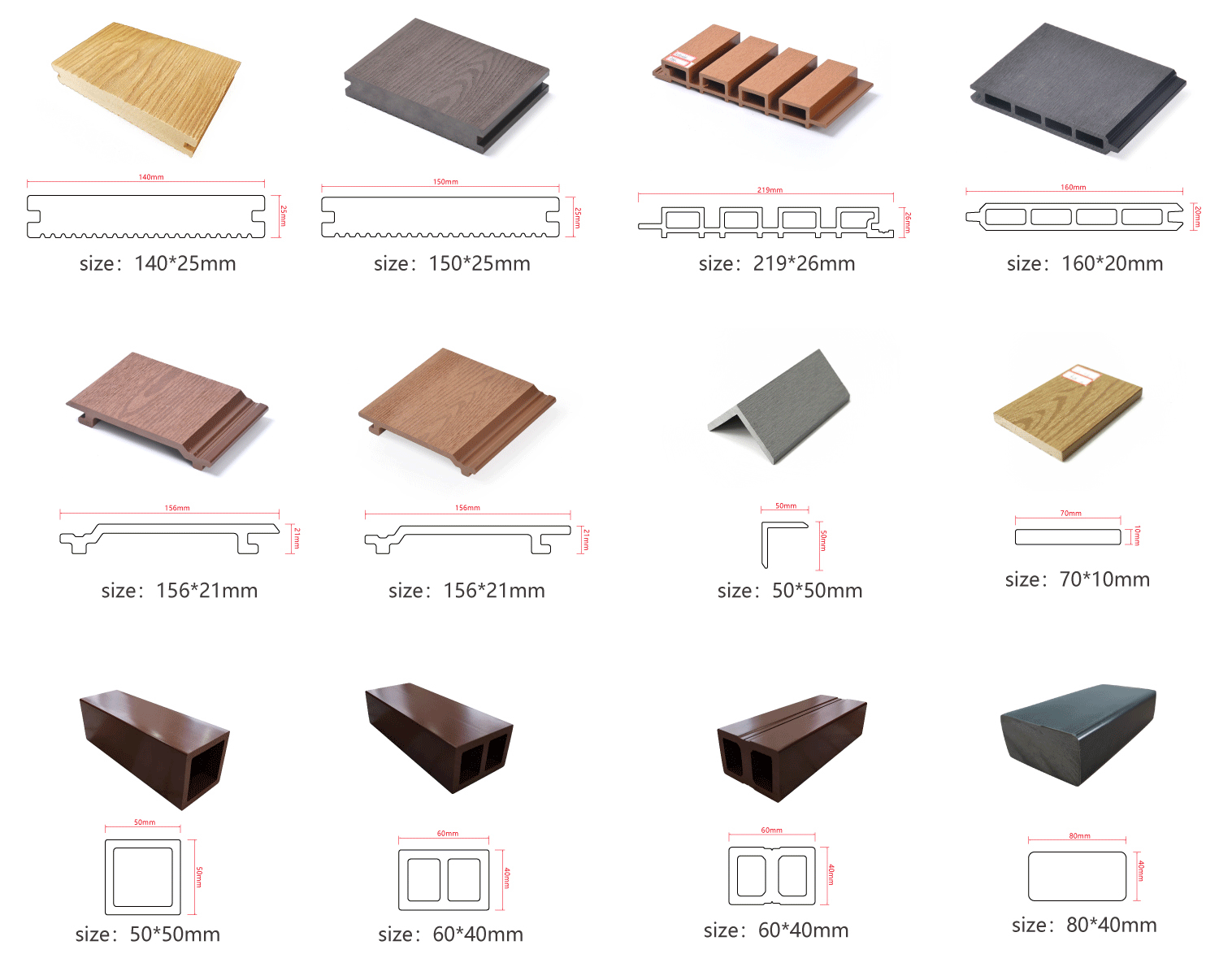

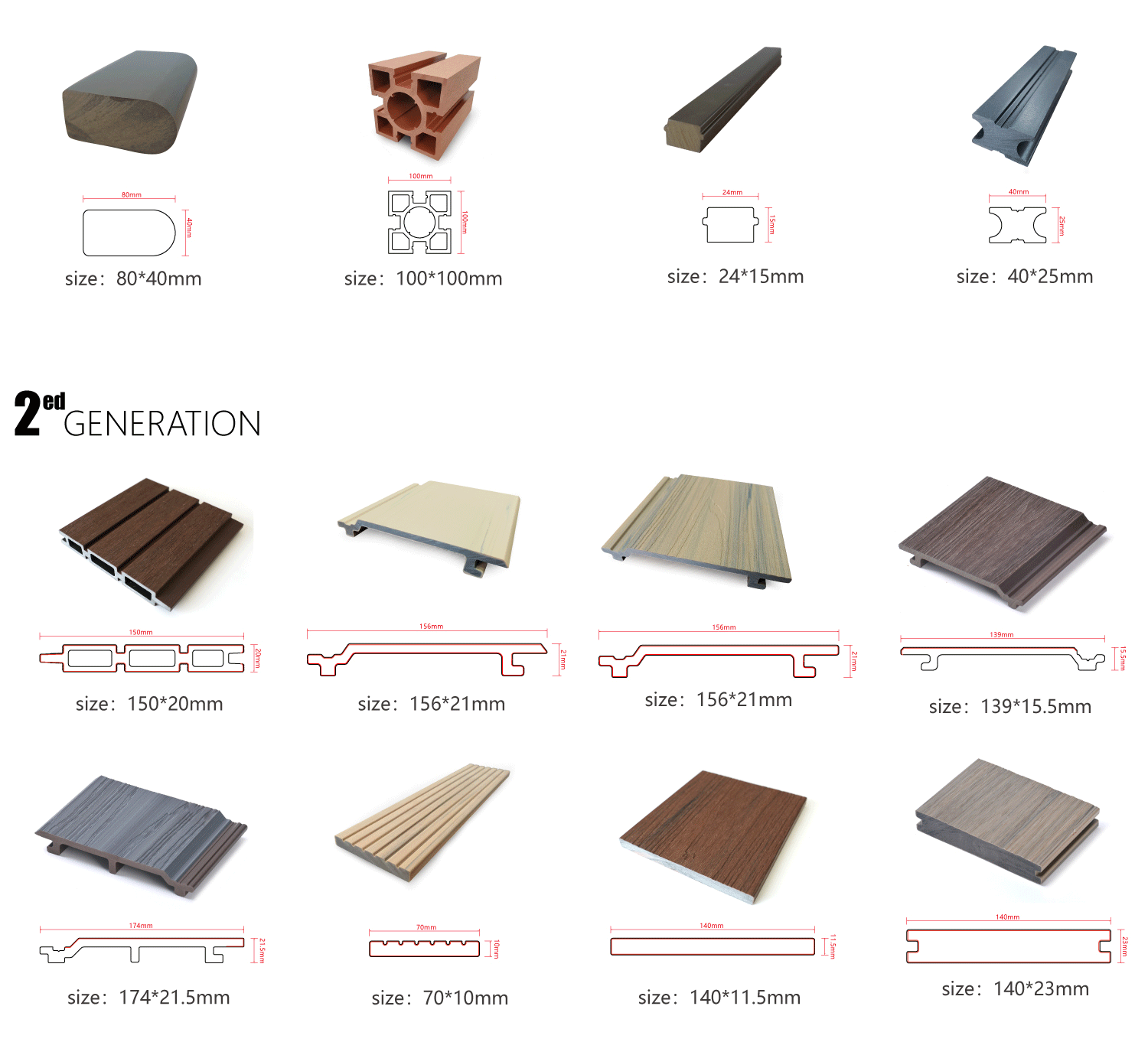

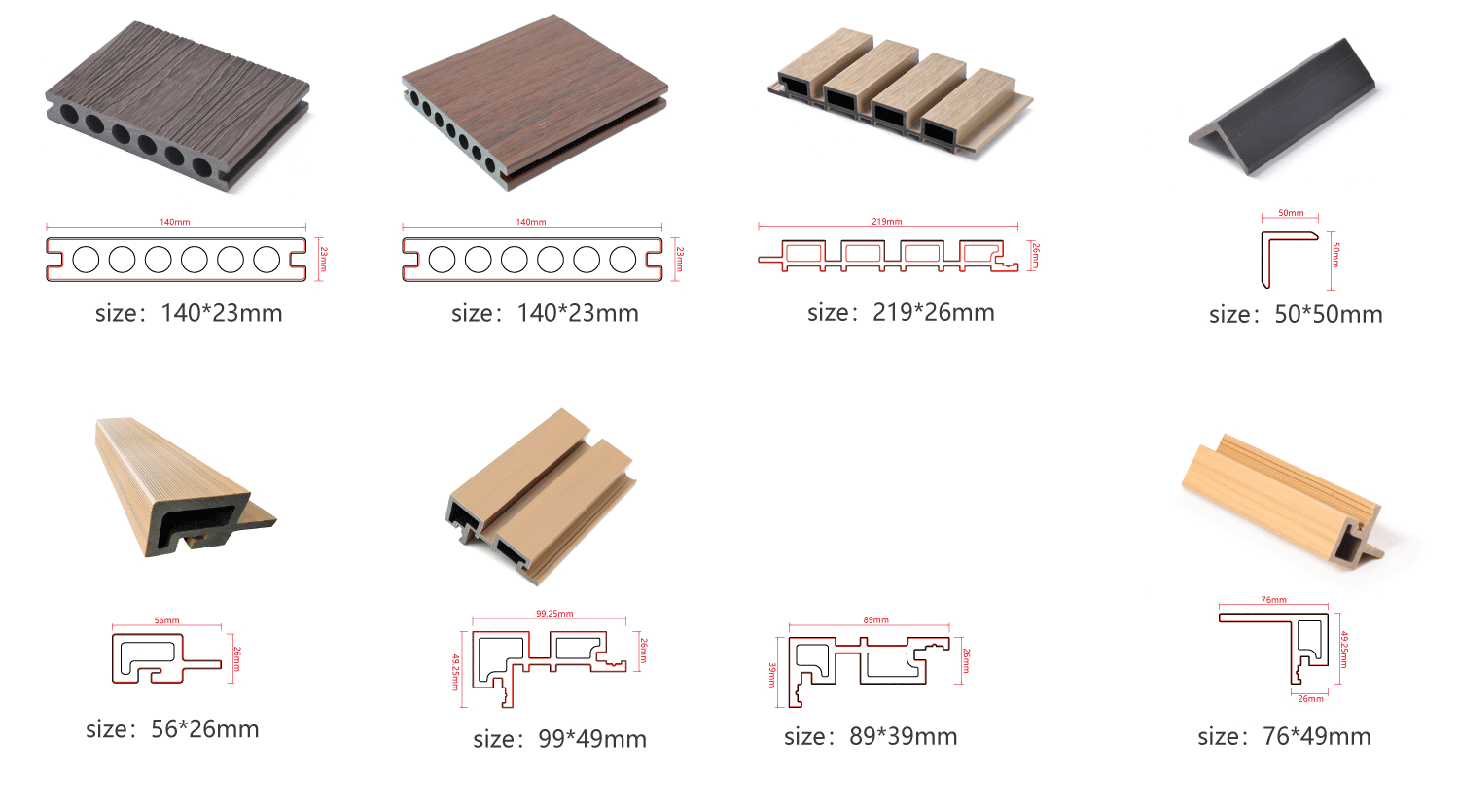

Product Catalog

+ -

-

Application Scenarios

+ -WPC outdoor wood plastic wall panels are suitable for various outdoor environments, such as outdoor balconies, parks, squares, landscape engineering, villa terraces, etc. Due to its waterproof, moisture-proof, and insect proof properties, it is particularly suitable for use in humid and high water environments.

Hot Selling

Hot Selling